Drilling stainless steel involves the process of creating holes in stainless steel surfaces using specialized tools known as drill bits. Stainless steel, known for its durability and corrosion resistance, requires precision and specific techniques when drilling.

The question often perplexes those seeking optimal results in their drilling endeavors. What is the best drill bit for drilling stainless steel? Selecting the right drill bit is paramount for efficiency and effectiveness in drilling through stainless steel.

When it comes to the best drill bit for drilling stainless steel, several factors come into play. High-speed steel (HSS) and cobalt drill bits are popular choices due to their durability and ability to withstand the hardness of stainless steel. Titanium-coated drill bits offer enhanced heat resistance, reducing friction during the drilling process.

The Challenge of Drilling Stainless Steel

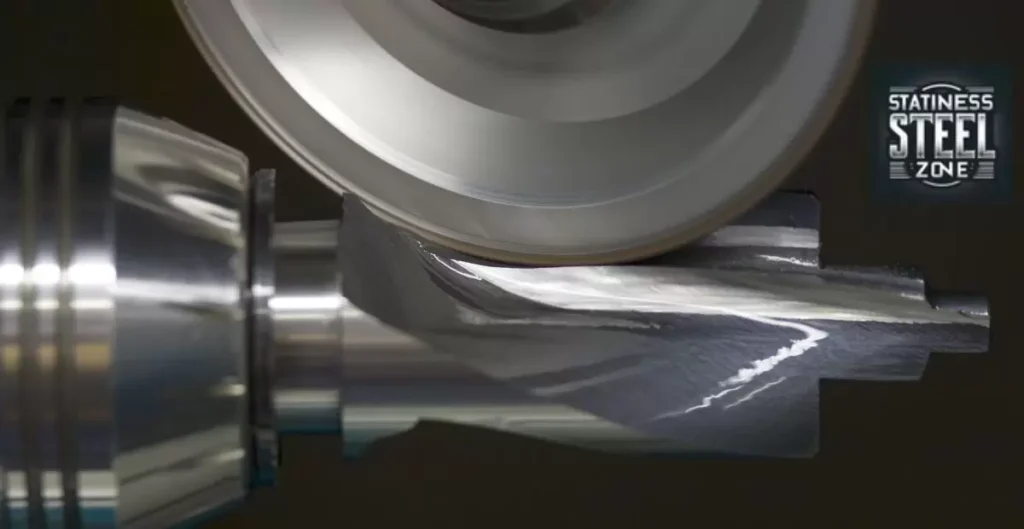

Drilling stainless steel poses a unique set of challenges due to its exceptional hardness and durability. The inherent toughness of stainless steel demands specialized tools that can cut through the material with precision and efficiency. This challenge is further amplified by the risk of heat buildup during drilling, potentially affecting the integrity of the stainless steel surface.

Achieving clean and accurate holes in this robust material requires not only the right techniques but also the selection of a drill bit that can withstand the hardness without compromising performance. The challenge of drilling stainless steel underscores the importance of using appropriate tools designed specifically for this demanding material.

What Sets the Best Drill Bit Apart

In the realm of, the quest for the best drill bit for drilling stainless steel is pivotal for achieving optimal results. What sets the best drill bit apart lies in its ability to address the unique characteristics of stainless steel. High-speed steel (HSS) and cobalt drill bits are favored for their durability and resilience against the hardness of stainless steel.

The best drill bit is distinguished by its capacity to cut through the material with precision, minimizing the risk of wandering and ensuring accurate hole placement. The coating of the drill bit plays a crucial role, with titanium-coated options providing enhanced heat resistance, reducing friction, and contributing to a smoother drilling experience.

Factors Influencing the Choice of Drill Bit

When faced with the task of drilling through stainless steel, selecting the right drill bit becomes crucial, and several factors play a pivotal role in making an informed decision. The material composition of the drill bit is a key consideration. High-speed steel (HSS) drill bits are renowned for their durability, making them a popular choice.

Cobalt drill bits are known for their enhanced heat resistance, providing durability in high-friction environments. Another critical factor is the coating of the drill bit. Titanium-coated drill bits offer an extra layer of protection against wear and tear, ensuring longevity.

The Best Drill Bit for Drilling Stainless Steel Applications

Navigating the myriad options to find the best drill bit for stainless steel applications involves understanding the unique characteristics that set certain drill bits apart. High-speed steel (HSS) drill bits are a popular choice due to their versatility and durability. They boast a general-purpose design that can handle various materials, including stainless steel, delivering reliable performance.

Cobalt drill bits, on the other hand, excel in high-temperature applications. Their composition, featuring cobalt alloy, enhances heat resistance and durability, making them ideal for challenging stainless steel drilling tasks. The best drill bit for stainless steel applications depends on the specific requirements of the task, with users weighing factors.

Popular Choices in Drill Bits for Stainless Steel

Choosing the best drill bit for drilling stainless steel involves considering popular options that are known for their effectiveness and durability. High-speed steel (HSS) drill bits are widely favored for their versatility and affordability. These bits are suitable for general-purpose drilling in stainless steel and offer a good balance between cost and performance.

Titanium-coated drill bits have gained popularity due to their ability to withstand high temperatures and reduce friction during drilling. The titanium coating enhances the hardness of the bit, providing an extended lifespan and improved performance in stainless steel surfaces.

Selecting The Right Tool for The Job

The process of selecting the best drill bit for drilling stainless steel goes beyond brand names or general preferences. Users must tailor their choice to the specific task at hand. For example, if the project involves routine drilling in stainless steel, high-speed steel (HSS) drill bits may be the go-to option due to their versatility and cost-effectiveness.

When handling demanding tasks in industrial settings, cobalt drill bits, prized for durability, are preferred. Yet, challenges arise as black residue on stainless steel may affect the pristine surface. Regular maintenance is essential to preserving stainless steel’s integrity.

Tips Of Best Drill Bit For Drilling in Stainless Steel

Drilling through stainless steel demands precision and adherence to specific techniques. To ensure successful drilling, it’s crucial to choose the best drill bit for drilling stainless steel based on the application’s requirements.

- High-speed steel (HSS) and cobalt drill bits are popular choices due to their durability and ability to withstand the hardness of stainless steel.

- Consider drill bits with a titanium coating for enhanced heat resistance, reducing friction during the drilling process.

- To avoid common pitfalls, use proper drilling techniques, such as starting with a pilot hole and gradually increasing the drill bit size.

- Maintaining a steady speed and applying consistent pressure helps prevent overheating and ensures a clean, accurate hole in stainless steel surfaces.

Prolonging the Lifespan of Drill Bits

To extend the lifespan of drill bits and maximize their effectiveness in drilling stainless steel, it’s essential to follow proper maintenance practices. After each use, clean the drill bits thoroughly to remove any debris or metal shavings that may compromise performance. Store drill bits in a designated case or organizer to prevent damage and ensure they remain sharp for future use.

Regularly inspect the drill bits for signs of wear or damage, and replace them if necessary. When drilling through stainless steel, use cutting fluid or a lubricant to reduce heat and friction, preventing premature wear. Sharpen drill bits as needed using a dedicated sharpener or replace them when they no longer provide clean and efficient cuts.

Table: Types of Drill Bits for Stainless Steel

| Drill Bit Type | Advantages |

| High-speed Steel (HSS) | Durable, suitable for general-purpose drilling in stainless steel. |

| Cobalt | Higher heat resistance, ideal for tough stainless steel applications. |

| Titanium-coated | Reduced friction, enhanced heat resistance for improved efficiency. |

FAQs

How do I choose the best drill bit for drilling stainless steel?

Consider the hardness of stainless steel and opt for drill bits such as High-speed Steel (HSS), cobalt, or titanium-coated variants based on the specific application requirements.

What techniques can enhance drilling precision in stainless steel?

Start with a pilot hole, gradually increase drill bit size, maintain a steady speed, and apply consistent pressure to achieve clean and accurate holes.

How can I prolong the lifespan of my drill bits when drilling stainless steel?

Regularly clean drill bits after use, store them properly, inspect for wear, use cutting fluid or lubricant, and sharpen or replace drill bits as needed for optimal longevity.

Conclusion

In the world of drilling stainless steel, choosing the right drill bit is like picking the perfect tool for a job well done. The best drill bit depends on factors like material composition, coating, and design. High-speed steel (HSS), cobalt, and titanium-coated drill bits stand out as reliable options, each with its unique advantages.

As you embark on your drilling journey through stainless steel surfaces, keep in mind the tips, the importance of precision, and the diverse options available. Armed with the knowledge of the best drill bits and how to care for them, you’re ready to tackle stainless steel projects with confidence and achieve holes that are not just drilled but masterfully crafted.